Page 2 sur 6

Re: Ghibli de Hongrie [ENG]

Publié : mar. 10 avr. 2018 15:21

par spacecadet

No check engine, no smell. I guess because it's just a small crack there was no visible leak. The visible leak was at the exhaust port of the head.

I thought about welding, but the places I've contacted with couldn't guarantee the outcome, I've just found a place who claims 100% success with thermal sparying of metal.

Re: Ghibli de Hongrie [ENG]

Publié : mar. 10 avr. 2018 16:13

par plm

spacecadet a écrit :

I've just found a place who claims 100% success, with thermal sparying of metal.

Can you ask them for an example of work? Or a sample?

Re: Ghibli de Hongrie [ENG]

Publié : mar. 10 avr. 2018 17:08

par Froggie

spacecadet a écrit :No check engine, no smell. I guess because it's just a small crack there was no visible leak. The visible leak was at the exhaust port of the head.

I thought about welding, but the places I've contacted with couldn't guarantee the outcome, I've just found a place who claims 100% success with thermal sparying of metal.

Interesting.

I thought drilling was necessary to block the crack tips, and welding to have a perfect re-bonding of the crack (plasma may only "coat" the substrate with fused powders).

But this video shows that it may work well if properly done:

https://www.youtube.com/watch?v=hoaPSaNYl34

Look in particular at how they pre-heat the substrate to high temps before starting thermal spraying and thereafter melt in a controlled way both the powders and the substrate to close the gap.

Also noteworthy is the fact that they have apparently drilled the cracked zone before starting the heating/spraying process as it is essential to avoid propagation of the crack at the tips.

Not sure however if stresses (promoting further cracks) may not develop during cooling... Probably needs some annealing afterwards.

Hope your shop does a good job!

Re: Ghibli de Hongrie [ENG]

Publié : mer. 11 avr. 2018 11:23

par spacecadet

The process is pretty much as you describe. Preparation is the same as when welding, drilling and grinding. They heat up the whole part so not only the small areas get high heat. Then comes the spraying and melting. Afterwards annealing, cool down time is around 2 days.

I also hope they do a good job

but they do similar works regularly and I have seen reference work.

Re: Ghibli de Hongrie [ENG]

Publié : mar. 24 avr. 2018 23:17

par spacecadet

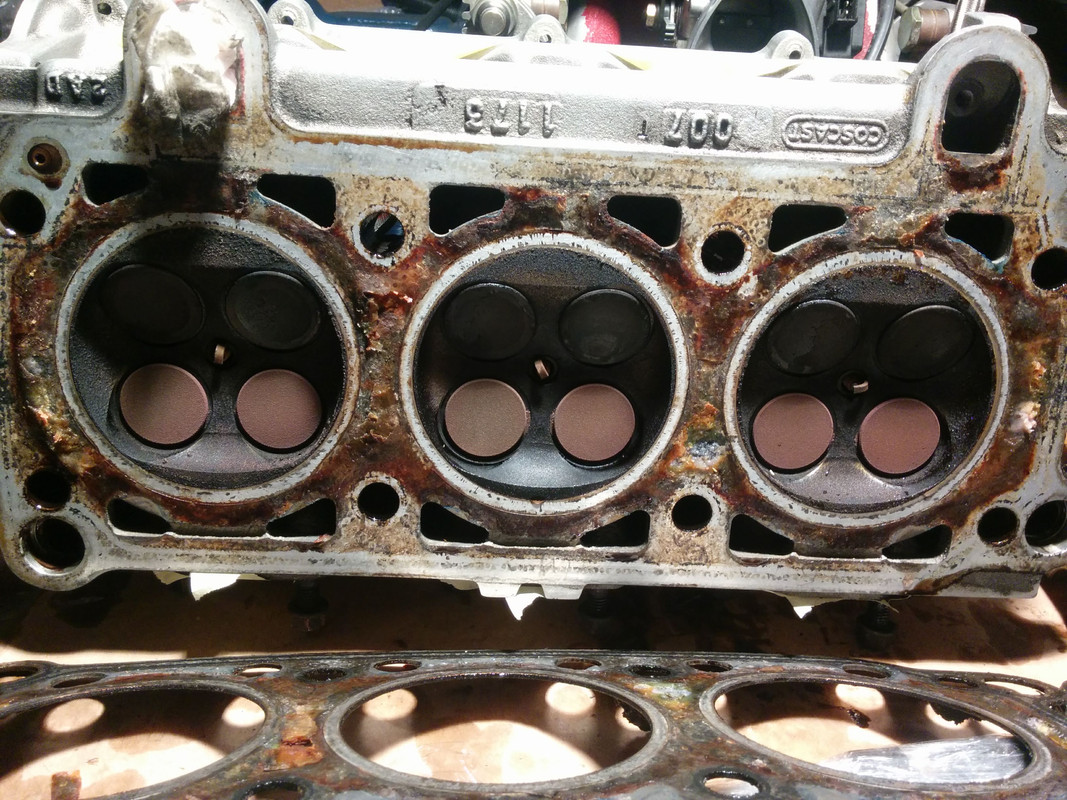

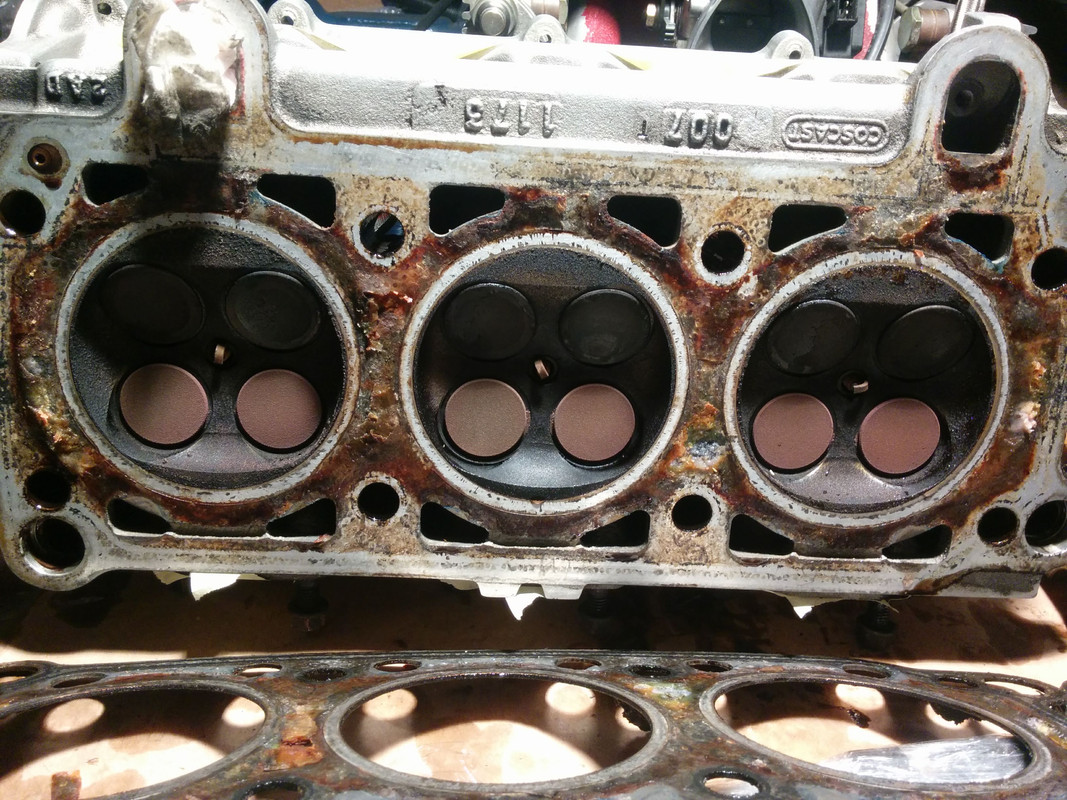

So here is the result after resurfacing. The repair was pretty expensive (because of the powder used in the process), but also included a crack test, which revealed a smaller crack on the other side. All in all 145 EUR + 35 EUR the resurfacing. Still cheaper than a used part. And I will probably do some grinding work to remove the protruding parts.

Re: Ghibli de Hongrie [ENG]

Publié : mar. 24 avr. 2018 23:49

par Froggie

Thx for the feedback and well done.

Btw, if you have some spare time, you should reload your previous pics in the thread (not visible anymore).

Just click on the image, then change the extension from postimage.org to postimage.cc in the web address

Re: Ghibli de Hongrie [ENG]

Publié : dim. 29 avr. 2018 11:39

par bay

Froggie a écrit :Thx for the feedback and well done.

Btw, if you have some spare time, you should reload your previous pics in the thread (not visible anymore).

Just click on the image, then change the extension from postimage.org to postimage.cc in the web address

C'est corrigé

Re: Ghibli de Hongrie [ENG]

Publié : sam. 26 mai 2018 20:30

par spacecadet

Yes, I've fixed the pictures

Finally did the leak down test, should have done much earlier. The results are really not good, nearly all the cylinders show 25% leakage, regardless the number there a lot of air is escaping at the exhaust valves.

https://www.youtube.com/watch?v=XyRx4Bmjmq0

I don't think this is acceptable, I fear this means the heads should be removed. Could be burnt valves (they are pretty white)? Any suggestion?

Re: Ghibli de Hongrie [ENG]

Publié : sam. 26 mai 2018 20:57

par Froggie

Goddam...that's annoying!

I'm no expert but wrt leaks, maybe only the valve seats may be reworked?

But then it may be worth rebuilding the whole heads.

Experts will chime in

Re: Ghibli de Hongrie [ENG]

Publié : lun. 28 mai 2018 13:00

par alpa

Yea this does not look right.

I'm sorry I did not read the entire thread. I guess you've checked first that there is a lash between cams and buckets ?

Your valves may have been burned if timing/richness was wrong and combustion was continuing with open valves.

Re: Ghibli de Hongrie [ENG]

Publié : lun. 28 mai 2018 13:06

par alpa

spacecadet a écrit :

So I can either adjust the difference between the exhaust and intake cams by changing the pin in the sprocket in the back, or just change the chain since I already have it. By the way found the manufacturer mark on the chain:

https://www.reginachain.net/ They mainly do chains for motorcycles, another Ducati connection like Nigusil?

Interesting ! Have you tried to contact them ?

I can not help about the shaft you tried to dismount. Honestly speaking I did not understand what you were trying to do.

Re: Ghibli de Hongrie [ENG]

Publié : lun. 28 mai 2018 19:37

par spacecadet

alpa a écrit :Yea this does not look right.

I'm sorry I did not read the entire thread. I guess you've checked first that there is a lash between cams and buckets ?

Your valves may have been burned if timing/richness was wrong and combustion was continuing with open valves.

Yes, double checked to be at TDC at the end of compression, and that there is a lash between the cams and buckets. First I though I'm at the wrong TDC, but unfortunately not.

I've measured AFR earlier with a wideband lambda, and that seemed to be ok (I don't remember the exact numbers) but that was after I've replaced the out of spec sensors. There was definitely a rich situation I think earlier.

alpa a écrit :Interesting ! Have you tried to contact them ?

Not yet, but I just wrote them an email. Will see.

alpa a écrit :I can not help about the shaft you tried to dismount. Honestly speaking I did not understand what you were trying to do.

Thanks, It's already done, it was just very tight. I had to remove the bearings first.

Re: Ghibli de Hongrie [ENG]

Publié : lun. 28 mai 2018 20:07

par alpa

spacecadet a écrit :

alpa a écrit :Interesting ! Have you tried to contact them ?

Not yet, but I just wrote them an email. Will see.

Oops, me too !

spacecadet a écrit :

alpa a écrit :I can not help about the shaft you tried to dismount. Honestly speaking I did not understand what you were trying to do.

Thanks, It's already done, it was just very tight. I had to remove the bearings first.

Ok I see.

For your information you can mount old (before ABS) axles with their wheel hubs on these hub carriers. Perfectly compatible. This allows mounting old rims with the 96mm instead of 98mm (or the opposite, don't remember) center distance.

Re: Ghibli de Hongrie [ENG]

Publié : lun. 28 mai 2018 21:03

par spacecadet

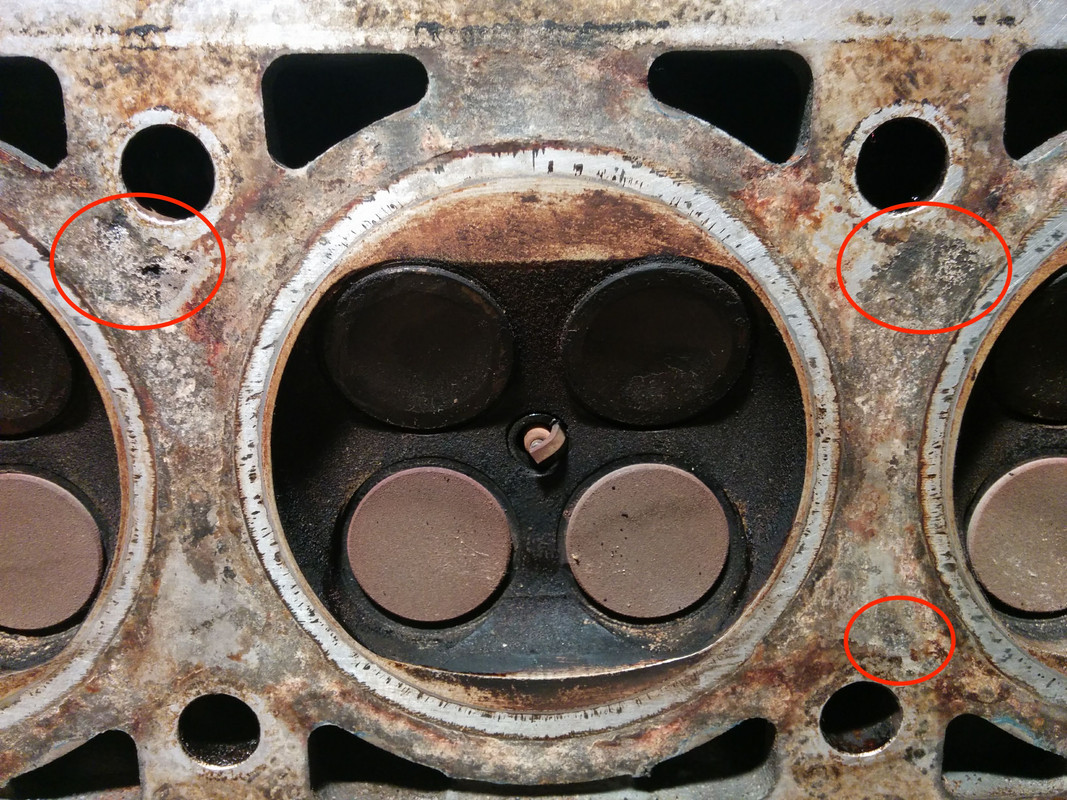

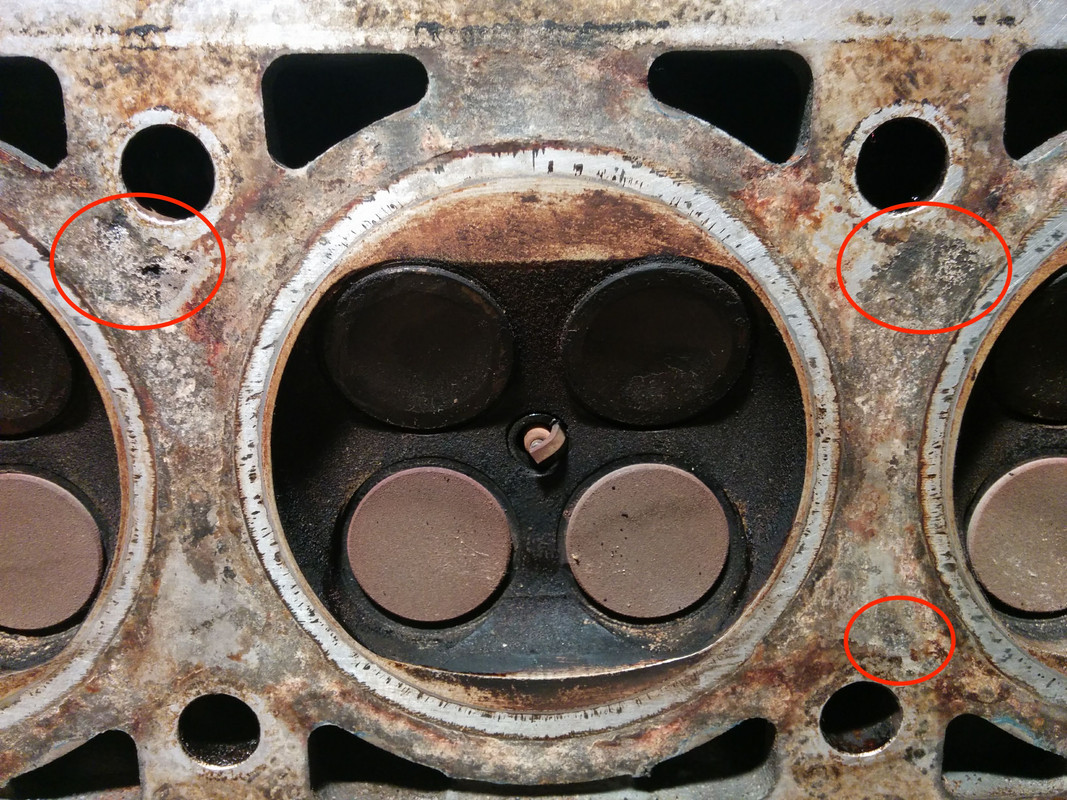

Forgot to show these pictures. One exhaust valve is leaking. Is this white color normal? Could it be because of the additives in the modern fuels or it's burned?

Re: Ghibli de Hongrie [ENG]

Publié : mar. 29 mai 2018 00:31

par alpa

Modern fuel is not unlike 30 years before and modern valves are similar to what we had on biturbo engines.

This white color is not unusual on exhaust valves. It forms a kind of very hard ceramic, not necessarily lean combution. You'll find the same on the piston crown. For sure it was not running rich. May be a bit too much white especially on valves themself.

I can show you beatifull pinkysh valves from 3200gt.

Re: Ghibli de Hongrie [ENG]

Publié : mar. 29 mai 2018 23:56

par spacecadet

That's good news. The results are still hard to believe for me, so I'll triple check everything once again.

Re: Ghibli de Hongrie [ENG]

Publié : lun. 25 juin 2018 09:16

par alpa

spacecadet a écrit :Yes, I've fixed the pictures

Finally did the leak down test, should have done much earlier. The results are really not good, nearly all the cylinders show 25% leakage, regardless the number there a lot of air is escaping at the exhaust valves.

https://www.youtube.com/watch?v=XyRx4Bmjmq0

I don't think this is acceptable, I fear this means the heads should be removed. Could be burnt valves (they are pretty white)? Any suggestion?

I've made leak tests on different engines this week-end.

Primatist (2L 24v probably totally rebuilt, low compressions, not enough power) and my 2.24v (engine on the bench, 120mkm): 20-25% of leakage, same on both.

430 18v with a 180mkm engine: 5%

222E (2.8 18v) : 0%

Would high leakage be due to low tension piston rings ?

Re: Ghibli de Hongrie [ENG]

Publié : mer. 27 juin 2018 08:50

par spacecadet

Interesting. For me most of the air was escaping through the exhaust valves, some through the intake but couldn't feel anything through the crankcase though the oil pan was not removed.

After a long hesitation I've removed the head on the weekend. Glad I did because the gaskets were fully deteriorated unfortunately even pitting the head in some places. I've also found one combustion chamber with really strange marks, but nothing on the corresponding piston. The piston is still on the top, I have to block the sleeves to turn over and see the cylinder wall. The other walls look nice with clearly visible machining marks.

I think this head will need resurfacing (or I have to find other ones) but I wonder if that's possible. The intake valve seats are angles are dangerously close to the surface of the head. The manual calls for measuring the combustion chamber with fluid and plexi glass that can't be laid on the surface as the valves are protruding.

Re: Ghibli de Hongrie [ENG]

Publié : mer. 27 juin 2018 09:08

par spacecadet

By the way, did you get an answer from Regina chains? I didn't...

Re: Ghibli de Hongrie [ENG]

Publié : mer. 27 juin 2018 09:32

par alpa

I did not get answer from Regina, not surprising, Maseralfa explained in Italy you have to call before writting to them

.

He'll try as a professional, he owns a parts business.

Your head looks like having had strong ping, ping melts down the surface. But it usually happens on pistons, not on the head. At least I have not seen such case but I don't have so much experience with this. Check piston crown when it's in TDC. These heads are extremely well designed so they are very well cooled. And pistons are forged. So it may be OK after some cleaning and surfacing.

Valves are OK and yes they are close to the surface but this is how F1 heads are

. It's written Coscast, not a mistake, it's Cosworth.

Head oxydation is not unusual on old engines. You'll see more once surfaced, removing 0.1mm may suffice.

Note that valve seats are very special (round shaped like on F1 engines, not angled) so don't allow any wanker to work on them. There is only one angle on them.